Product overview

Description

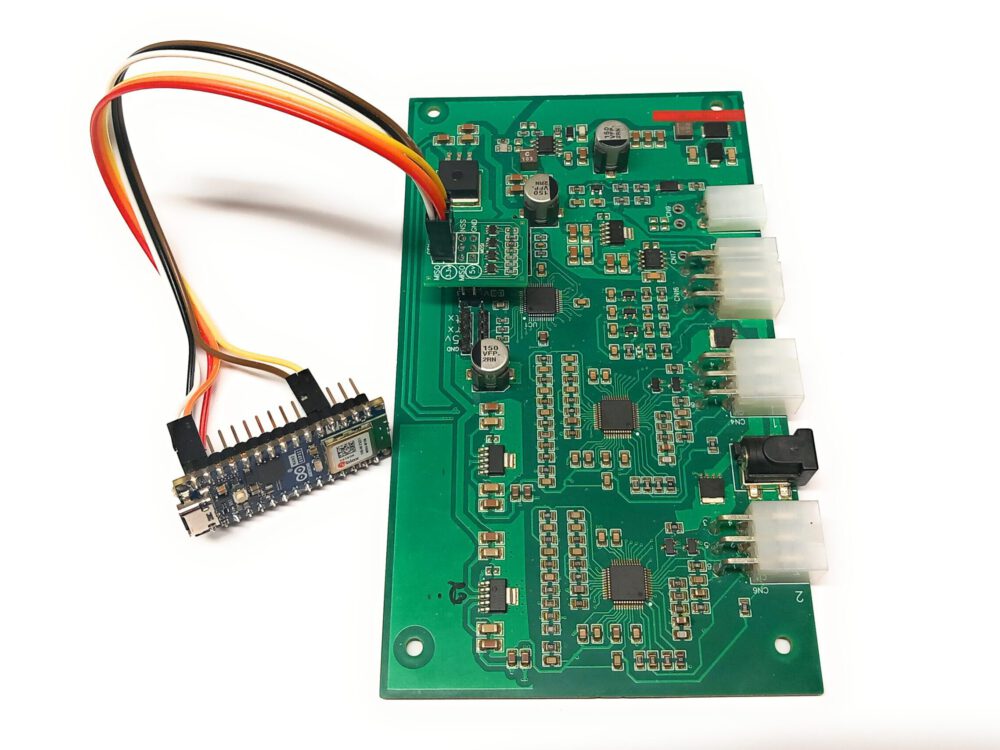

The module measures the percentage of oxygen contained in the smoke or air, calculate the lambda and AFR (air-fuel ratio of combustion), at two points independently, as it can be connected to two wideband lambda probes. This module also has three analogue inputs and measures rpm, and battery voltage..

It can be integrated into any project quickly and easily, without wasting arduino board resources. All this thanks to the microcontroller integrated on the board that controls the temperature of the probe, performs all the calculations, monitors the diagnostics, and sends the data via SPI to the arduino when requested.

The library for arduino “LambdaX2_rpm.h” will take care of the control of the board, so that you can easily get the measurement. It will simply take care of the communication and some change of units, with it you can easily incorporate the module to your project easily and quickly and without previous knowledge.

It has a 5V output that will allow your arduino or small project to be powered, with a current of less than 300mA. The power supply to this module has been improved to reduce the heat generated and reduce energy consumption.

The microcontroller integrated in the module is in charge of:

- Diagnostics.

- Calculation of %O2 and AFR.

- With variable digital filter.

- With pressure variation compensation. (If the arduino sends it the smoke pressure).

- With temperature variation compensation.

- Max data sampling rate 100 samples / second

- Temperature control and heating of the two lamda probes.

- Calculation of the rpm value.

- With variable filter

- With parameters for adjusting the relationship between number of signals and rpm.

- Measurement of 3 analog inputs 0-5V that can be connected to external sensors..

- Communication via SPI BUS with the arduino board. In the arduino through the library you will be able to turn on and off the module, request a value, etc.

- Communication via CAN bus with an arduino board (Arduino UNO R4 Minima or Wifi, with the addition of a CAN transceiver). In the arduino through the specific library for the can bus you can turn on and off the module, ask for a value, etc.

- It stores configuration and setting data in its non-volatile memory.

All features

- Microcontroller integrated on the board: Microchip Technology dspic33EV128GM004

- 2 x Wide range air fuel sensor control interface STMicroelectronics l9780.

- Compatibility with wideband lambda probe BOSCH lsu 4.9

- Compatibilities with 5V arduino boards.

- Arduino UNO R3.(SPI comunication)

- Arduino UNO R4 mínima.(SPI comunication)

- Arduino UNO R4 WIFI.( SPI comunication)

- Arduino MEGA.( SPI comunication)

- Others, compatible but not tested.

- Compatible with 3.3 V Arduino boards via 3.3-5 V SPI adapter.

- Arduino Nano. (SPI comunication, with SPI adapter.)

- Others, compatible but not tested.

- Safe and efficient power supply to the arduino from 12V transformer input or car battery.

- Reverse polarity protection, Note: only the electronics are protected, if connected in reverse the probes will be heated.

- Transient voltage suppressor.

- EMI filter.

- Buck converter.

- The digital circuit allows a power output with a 5V voltage of 300mA to power the arduino and small projects, such as a display or Bluetooth module. Through the H8 jumper.

- Noise reduction in the measurement. The analog circuit has its own LDO which isolates it from the noise of the digital circuit.

- SPI connections are short-circuit protected.

Library of functions

The library contains functions for sending commands, taking data and making more advanced settings, the main functions do the following tasks:

- Power on/off.

- Configuration.

- Reading data

- 2 x O2

- 2 x Lambda

- 2 x AFR(diesel, gasoline, other fuels…)

- 3 x Analog inputs.

- rpm

- Battery input voltage

- Other more advanced.

- Diagnostics

- Adjustment or calibration

- Enable or Vary the digital filter

- Enable o Enable compensation for pressure variation.

- Sending pressure data from the arduino to the module.

- Auto shutdown time adjustment.

- Parameter settings for rpm calculation.

The functions of the “LambdaX2_rpm.h” library can be found in file XXXX.

The “Lambda_rpm.h” library can be downloaded here: XXXX.

Library of functions, for CAN communication:

A library of functions “LambdaX2_rpm_CAN.h” will be created to be able to communicate with the module with an arduino through a CAN bus, which will be equivalent to the library “LambdaX2_rpm.h” but using a CAN bus instead of a SPI bus. Not available yet.

Software available for arduino:

- Display on Arduino IDE, serial monitor.

- PLMEX2_RPM_1.0.ino: Basic operation to get started. Sends serial data to the arduino IDE. rpm, %O2 and AFR.

- PLMEX2_RPM_1.1.ino: Basic operation to get started. Sends serial data to the arduino IDE, rpm,%O2 and AFR, V bat, Diagnosis, State…

- PLMEX2_RPM_2.0.ino: Basic operation to get started 2. Sends serial data to the arduino IDE, allows adjustment of air to 20.95% oxygen, to compensate for probe errors, and pressure due to geodesic height …., diagnostic display.

- PLMEX2_PM _2.1.ino: Basic operation to get started 2. Sends serial data to the arduino IDE, allows adjustment of air to 20.95% oxygen, to compensate for probe errors, and pressure due to geodesic height …., diagnostic display. Set in the non-volatile memory the rpm calculation parameters.

- PLMEX2_RPM_3.0.ino: (available soon) Sends serial data to the arduino IDE, allows adjustment of air to 20.95% oxygen, to compensate for probe errors, and pressure due to geodesic height …., diagnostic display, digital filter setting, auto-off time setting.

- PLMEX2_RPM_3.1.ino: (available soon)(Pressure sensor required) Sends serial data to the arduino IDE, allows adjustment of air to 20.95% oxygen, to compensate for probe errors, and pressure due to geodesic height …., diagnostic display, digital filter setting, auto-off time setting. Continuous compensation of the error generated by the pressure dependence of the wideband lambda sensor signal (0.5 to 2.5 Bar). The arduino will need to send the gas pressure to the module continuously.

- Display on an LCD screen, (Library “LiquidCrystal_I2C.h”, display (LCD1602) with (LCD I2C( controller)).

- PLMEX2_RPM_4.0.ino: Display rpm,%O2, lambda, AFR on an LCD screen.

- PLMEX2_RPM_4.1.ino: Display rpm,%O2, lambda, AFR on an LCD screen.. Display of the state when the measurement is not valid. when When D8 is connected to ground, a lambda probe setting of 21.95%O2 is made and stored in the module’s non-volatile memory. (acting on falling edge), when D7 is connected to ground, it switches the value to be displayed between AFR and %O2.

- Display on a Smartphone APP.

- PLMEX2_RPM_5.0.ino: (HM10 bluetooth low energy module required). sends the data (Displays rpm, O2, AFR, Lambda,Vbat) to a mobile application via Bluetooth, where it can be displayed and/or stored.

- Display on a Smartphone APP and LCD, (Library “LiquidCrystal_I2C.h”, display (LCD1602) with (LCD I2C( controller)))..

- PLMEX2__RPM_5.1.ino: (HM10 bluetooth low energy module required). sends the data (Displays rpm, O2, AFR, Lambda,Vbat) to a mobile application via Bluetooth, where it can be displayed and/or stored. Simultaneously displays rpm, %O2, or AFR values on an LCD display. When D8 is connected to ground, a lambda probe setting of 21.95%O2 is made and stored in the module’s non-volatile memory. (acting on falling edge), when D7 is connected to

- Datalogger of the operation of an automotive engine:

- PLMEX2__RPM_6.0.ino: datalogger of the operation of an automotive engine. Data collection of %O2, AFR, Lambda, RPM and storage on an SD card.

- Adjustment, error compensation, writing of non-volatile memory of the module.

- PLMEX2_RPM_7.0.ino: This program is used to set the values of the non-volatile memory of the board for the following settings:

- O2: Set the filtering value.

- O2: Set the automatic switch-off time of the lambda probe heating.

- O2: Enable/disable the pressure compensation.

- O2: Adjustment and calibration parameters.Adjustment and calibration, to eliminate all errors such as: Height dependent pressure variation, manufacturing tolerances of the broadband lambda probe and the module….. setting the air to 20.95% oxygen.

- rpm: Set the filtering value.

- rpm: Adjustment of the signal-to-turn ratio parameters.

- …

- PLMEX2_RPM_7.0.ino: This program is used to set the values of the non-volatile memory of the board for the following settings:

- Data display on a large-format touch screen.

- PLMEX2_RPM_8.0.ino: Data display on a large-format touch screen.

- PLMEX2_RPM_9.0.ino: Display data on a large format touch screen and store the data in a .CSV file on an SD card.

Smartphone App(HM10 bluetooth module required).

Switches the lambda sensor, displays battery voltage, rpm, oxygen percentage, lambda and AFR (air-fuel ratio) for different fuels on the smartphone screen. Is available for the following smartphone platforms:

- Android

- IOS(not currently available, available soon)

It will also be programmed to use bluetooth communication through arduino boards such as Arduino UNO R4 wifi, or arduino NANO with built-in bluetooth. Not yet available..

Required components

- Wideband lambda sensor control module for Arduino. Controlduino 01M30V00.

- 2 x Wideband lambda probe connection cable (connector 1813139-1) with Shield (Connector 5557).

- 2 x Lambda probe, Bosch LSU4.9 or compatible.

- Power Supply(only one required).

- 12V battery and cable with Jack plug.

- 12V AC/DC adapter, I>6A.

- HM10 Bluetooth low energy module. (Only necessary for use with the smartphone applicatión).

- Arduino board with USB cable.

- Module with CAN transceiver, to connect to the arduino, (only for the sketches that use CAN Bus)